Have any Questions?

+86 516 6662 7071

Have any Questions?

+86 516 6662 7071

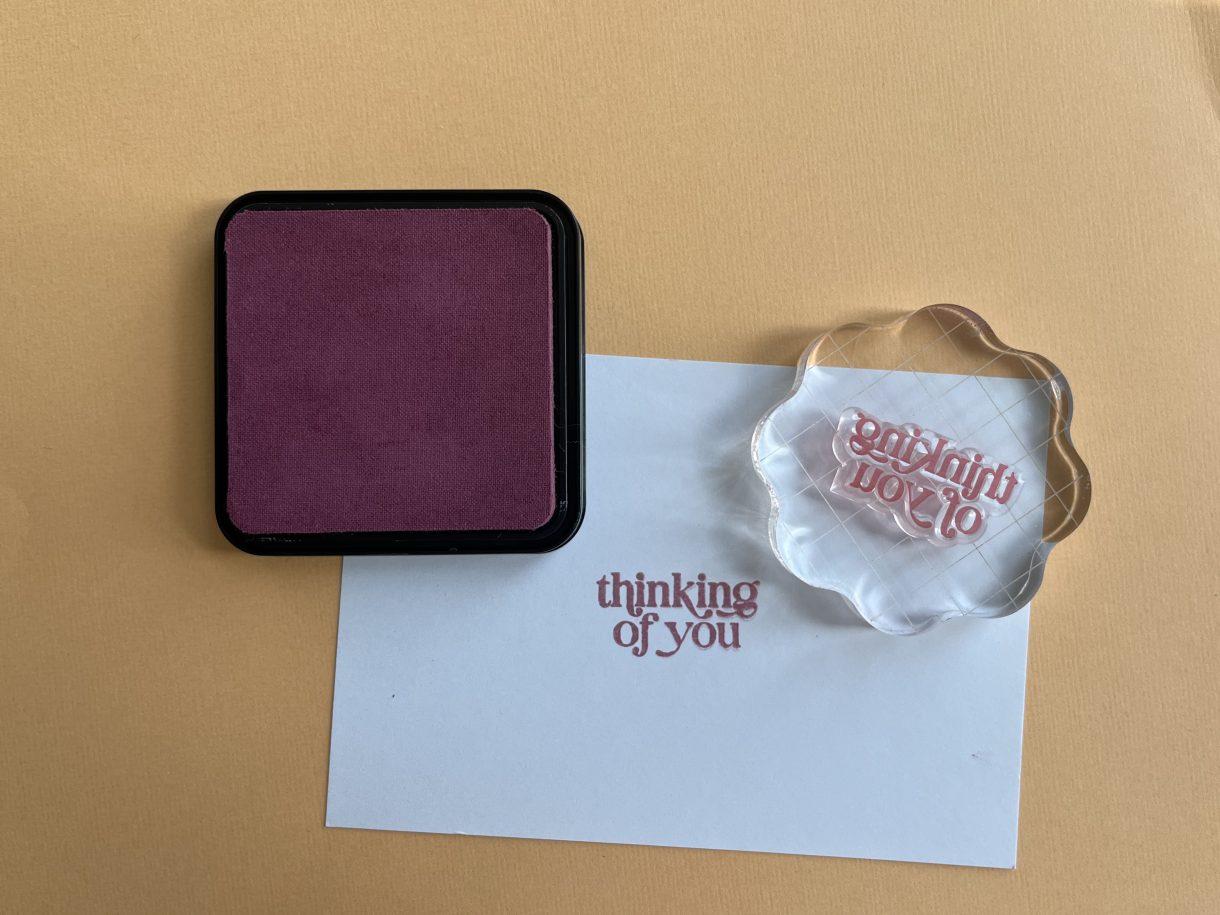

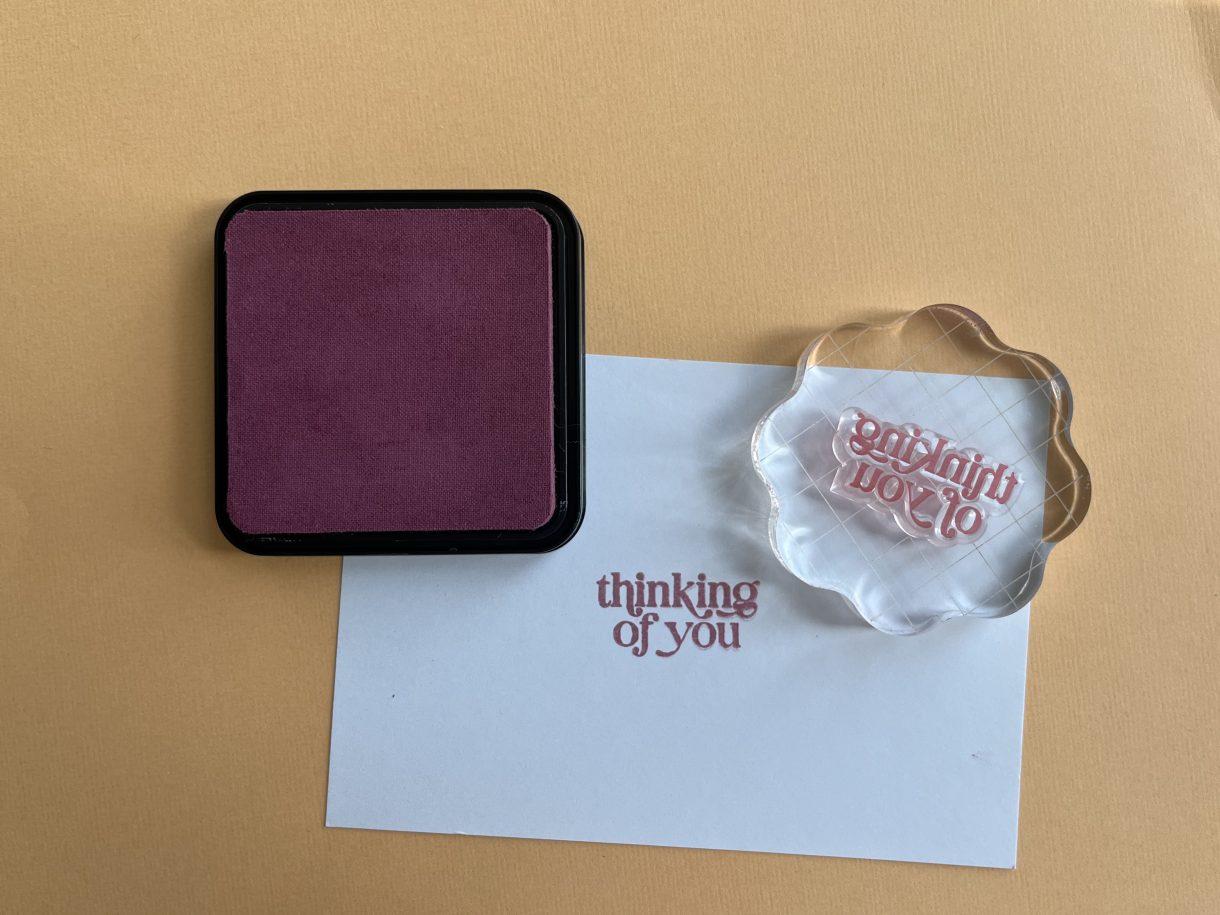

Photopolymer Stamps are highly popular tools used for crafting, commercial branding, and creative projects. These stamps are made from light-sensitive polymers that cure under UV light, making them durable, versatile, and perfect for creating intricate designs.

What Is a Photopolymer Stamp?

A Photopolymer Stamp is a type of stamp made using photopolymer material, a light-sensitive resin that hardens when exposed to ultraviolet (UV) light. These stamps are flexible, clear, and capable of capturing fine details, making them ideal for a wide variety of stamping applications.

Features of Photopolymer Stamps

1. High Precision:

• Captures intricate designs and fine details.

• Perfect for logos, text, and artistic patterns.

2. Transparent Design:

• Makes it easy to align the stamp accurately on the surface.

3. Durability:

• Resistant to wear and tear, enabling long-term use.

4. Eco-Friendly:

• Often made with non-toxic, biodegradable materials.

5. Versatile Compatibility:

• Works with various inks, including dye-based, pigment-based, and archival inks.

Applications

Photopolymer stamps are used in various industries and for numerous purposes, such as:

1. Arts and Crafts:

• Card-making, scrapbooking, and hand-lettering.

• Perfect for creating decorative patterns on paper, wood, fabric, and more.

2. Business and Branding:

• Creating custom logos or seals for packaging.

• Branding materials like business cards or labels.

3. Personalized Gifts:

• Custom stamps for weddings, anniversaries, or special occasions.

• Ideal for making unique stationery or gift tags.

4. Industrial Uses:

• Marking parts with serial numbers or batch codes.

• Stamping surfaces in manufacturing or packaging.

Advantages of Photopolymer Stamps

1. Customizability:

• Easy to design and produce custom shapes and patterns.

2. Crisp Impressions:

• Produces clean and sharp images without smudging.

3. Ease of Use:

• Adheres well to acrylic blocks for quick and efficient stamping.

4. Reusability:

• Washable and reusable without losing quality.

How Are Photopolymer Stamps Made?

1. Design:

• Create the design digitally and print it on a transparent film.

2. Exposure:

• The photopolymer material is exposed to UV light with the design film, hardening the exposed areas.

3. Washing:

• Unexposed areas are washed away, leaving the desired stamp design.

4. Drying and Curing:

• The stamp is dried and further cured for durability.

5. Cutting:

• The finished stamp is cut into shape and mounted (if necessary).

How to Use a Photopolymer Stamp

1. Prepare the Stamp: Attach the stamp to an acrylic block.

2. Ink the Stamp: Evenly apply ink to the design surface.

3. Press and Stamp: Position and press the stamp firmly on the desired surface.

4. Clean the Stamp: Wash the stamp with water or a gentle cleaner after use.

Care and Maintenance

• Clean Properly: Use water or a stamp cleaner to remove ink residue.

• Avoid Direct Sunlight: Store in a cool, dry place to prevent degradation.

• Handle Gently: While durable, photopolymer stamps can tear if mishandled.

Why Choose Photopolymer Stamps?

Photopolymer stamps are the go-to choice for anyone looking for precision, versatility, and durability. Whether you’re a DIY crafter, an artist, or a business owner, these stamps offer unmatched quality for all your stamping needs.

Explore Our Photopolymer Stamps

Custom Designs: Let us bring your unique ideas to life with fully personalized photopolymer stamps.

Ready-to-Use Sets: Choose from a variety of pre-made designs for crafting and business needs.

Bulk Orders: Perfect for businesses looking for high-quality, reliable stamping solutions.

Contact us today to learn more or to get started with your photopolymer stamp project!